Bhoodan Pochampally, a town in Telangana, located about 40 km from Hyderabad, is renowned for its exquisite Pochampally silk sarees, also known as Pochampally Ikkat sarees. These sarees are crafted using the traditional Tie & Dye technique on a throw shuttle pit loom, with each saree typically taking between one week to 10 days to complete. The designs on these sarees are often inspired by nature, animals, and geometric shapes. The hallmark of this region’s rich weaving tradition.

In South India, Ikat is also referred to as Ikkat. The word ‘Ikat’ itself is derived from the Malaysian-Indonesian term meaning “to bind.”

Materials Used in Pochampally Ikkat Sarees

- Silk Yarn: The primary material used is pure Mulberry silk yarn, often sourced from Bangalore. For both the warp and weft, 22 denier silk yarn is used.

- Dyes: Organic dyes are employed in the dyeing process to achieve vibrant and long-lasting colors.

Tools Used in Weaving Pochampally Ikkat Sarees

- Plastic Pirns: Utilized for winding the yarns.

- Handloom: The traditional loom used for weaving Ikat silk sarees.

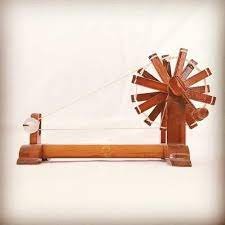

- Spinning Wheel: Used to wind the yarns onto the pirns.

- Bobbins: The dyed yarns are wound onto these bobbins for warping.

- Throw Shuttle: Employed to insert the weft yarns during the weaving process.

- Creels: A stand-like structure on which the fully wound bobbins of silk yarns are placed according to the warping pattern.

Step-By-Step Weaving Process

1. Yarn Preparation

Raw Mulberry silk yarn, sourced from Bangalore, arrives in bundles coated with a protective layer of chemical oil. To remove this oil and reveal the silk’s natural white color, the yarn is boiled in water with bleaching powder for about an hour. After boiling, the silk becomes soft and lustrous.

2. Setting Yarn into Spools & Cones

Once boiled, the yarn is transferred to a large charkha (spinning wheel). Each single thread is carefully aligned and wound onto spools or cones. If any yarn breaks during this process, it is meticulously tied.

3. Setting the Yarn on the Asu Machine

The yarn is then placed onto the Asu machine, an automatic yarn winding machine introduced in 1999. This machine winds the yarn in a specific pattern on a triangular frame, helping to mark the design on the yarn. The Asu machine has significantly reduced the manual winding process from six hours to just one and a half hours.

What is Asu Machine?

The Laxmi Asu Machine is an automatic yarn winding machine used in Pochampally Ikat weaving. It automates the traditional Asu process, where yarn is wound around semi-circular pegs 9,000 times to create patterns. The machine, featuring a microcontroller and motor, reduces the manual winding time from six hours to just one and a half hours, enhancing efficiency.

4. Marking the Saree Design

Before weaving begins, the saree design is meticulously planned on graph paper by skilled artisans. This design is then marked on the yarn wound on the triangular frame, a few times on the rectangular frame. Various intricate Ikat designs are possible, including:

- Navratan Design

- Madthasu Design

- Telia Rumal Design

- Patola Design

- Leheria Design

- Simple Geometric Ikat Designs

- Cambodian Design

- Twill Ikat

5. The Tie & Dye Process

This crucial step in making Ikat sarees involves tying the yarn tightly with pieces of tire tubes and cotton threads. The tying is done based on the desired motifs and patterns. For example, to create a blue saree with green motifs, the yarn is tied tightly where the green motifs will appear, leaving the rest exposed.

The yarn is then dipped into a dye bath (e.g., blue dye), dried under the sun, and the process is repeated for any additional colors (e.g., green) for motifs. The dye adheres to the exposed areas, and after drying, the tied sections are untied, revealing the intricate pattern. This tie-dyed yarn is used either as warp or weft yarn, or sometimes both, in double Ikat designs. More about single ikat & double ikat

7. Weaving the Silk Yarn

This is where the true artistry of Pochampally Ikat comes to life. Weaving involves the interlacing of two sets of yarn – the warp and the weft.

Weaving a single Pochampally saree involves approximately 11,800 interlacements. So fly-shuttle has to mover 11,800 times for a single saree.

The handloom facilitates this interlacement without the use of electricity, relying solely on the skill and rhythm of the weaver. The process requires precise coordination between the weaver’s hands and feet, creating a harmonious rhythm that results in a beautifully woven Pochampally saree.

Resouces: https://www.dsource.in/resource/ikat-saree-weaving-sambalpur-orissa/introduction

FAQ’s

Pochampally is a town in the Bhuvanagiri district of Telangana. Pochampally is famous for its exceptional Ikat weaving technique, rich cultural heritage, skilled craftsmanship, and the distinctive beauty of its handwoven sarees and other textile products. You can see a lot of weavers in the village follow the ikkat dyeing to make sarees, bedsheets, sico sarees & fabrics, dress materials, and more. Know more about Pochampally.

In Pochampally, learn about handloom-made textiles at Handloom Park or from weavers units, shop for exclusive Pochampally silk sarees directly from weavers, and engage with local artisans. Explore the town’s rich cultural heritage and enjoy its natural beauty. Don’t miss the vibrant local markets and making process of world-famous ikat fabric. Know more about Pochampally

Pochampally village or town is located 50km away from Hyderabad, the state capital. It is famous for ikat weaving technique, rich cultural heritage, skilled craftsmanship, the beauty of its handwoven sarees, and other textile products. Know more about Pochampally

Pochampally offers authentic Ikat sarees at popular shops like Raja Rajeshwari Handlooms, Lakshmi Devi Ikkat Silks, SN Handlooms, DSR Weaves, Pochampally Weavers Society, Shilpa Weaves, and Vikas Handlooms. These stores provide exquisite silk and cotton sarees, dress materials, and lehengas, showcasing the village’s rich weaving tradition.

Pochampalli village is in Yadadri Bhuvanagiri district, Telangana, about 40 km from Hyderabad. It is world-famous for Pochampally Ikat sarees and is also known as Bhoodan Pochampally.

Ikat is not specific to a single state; it is a traditional fabric-making technique used in various cultures around the world. However, it is particularly notable in countries such as India, Indonesia, Japan, and Central Asia. In India, states like Gujarat, Odisha, and Telangana (Pochampally) are well-known for their unique styles of Ikat weaving. For example, the Patola of Gujarat and the Bandha of Odisha are famous types of Ikat.

The Laxmi Asu Machine is generally priced between ₹18,000 and ₹25,000, depending on the model, features, and seller. The cost varies with the type of machine—about ₹18,000 for semi-automatic versions, around ₹20,000 for improved models, and up to ₹25,000 for fully automated or latest versions. Regional differences and vendors may also slightly affect the final price.

Chintakindi Mallesham is a Padma Shri awardee and innovator from Telangana, best known for inventing the Laxmi Asu Machine. Born in the village of Sharajpet into a weaver’s family, he created the machine to reduce the physical strain on women weavers, especially his mother, during the labor-intensive Asu process. His invention revolutionized Pochampally Ikat weaving by improving speed, quality, and productivity, while also preserving traditional craftsmanship.

Mulberry silk yarn is used, and it is sourced from Bangalore. For both the warp and weft, 22 denier silk yarn is used while making.

It takes around one week for a weaver to make one Pochampally silk saree, working 9 hours a day.